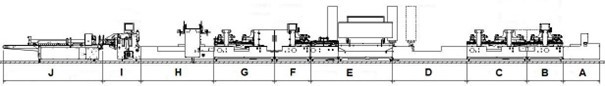

A-J

- main belt speed 10-500m/min

- Wireless remote control with inductive charging

- additional remote control (alternating operation, one remote control in the charger, the other in use)

- remote diagnosis via the Internet (REMOTE SEVICE)

- large 2 readable touch screens in section F and I

- Electronic control of gaps between cartons

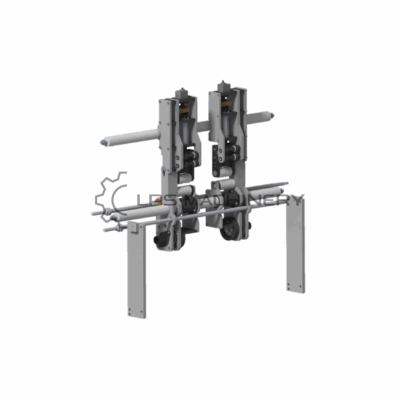

- drive wheels with a diameter of 188 mm for very stable operation and no belt slippage

- side frames made of high-quality steel 20 mm thick

- conveyor frames made of high-quality steel 15mm thick

- drive of the conveyors with shafts by means of plastic couplings guaranteeing vibration-free and long-lasting operation

- powerful, energy-efficient motors in IE3 (energy saving) standard

- shaft drive between sections

- machine prepared mechanically and software for the assembly of the gluing and control system

- motorized all conveyors with buttons for manual adjustment, correction

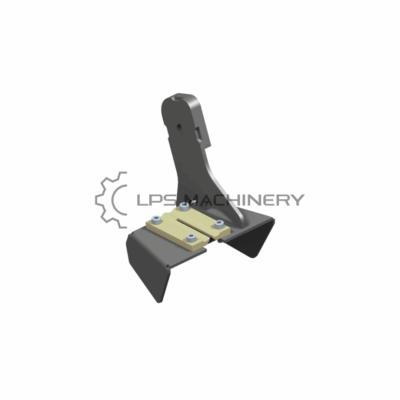

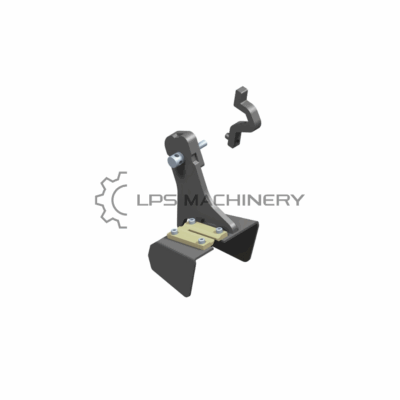

- LPS CLAMPING SYSTEM – an innovative tooling clamping system for production anywhere on the machine

- LPS REVERSE INCH – movement of the machine in reverse gear

- LPS AUTO GP – possible operation of the gluing motor only

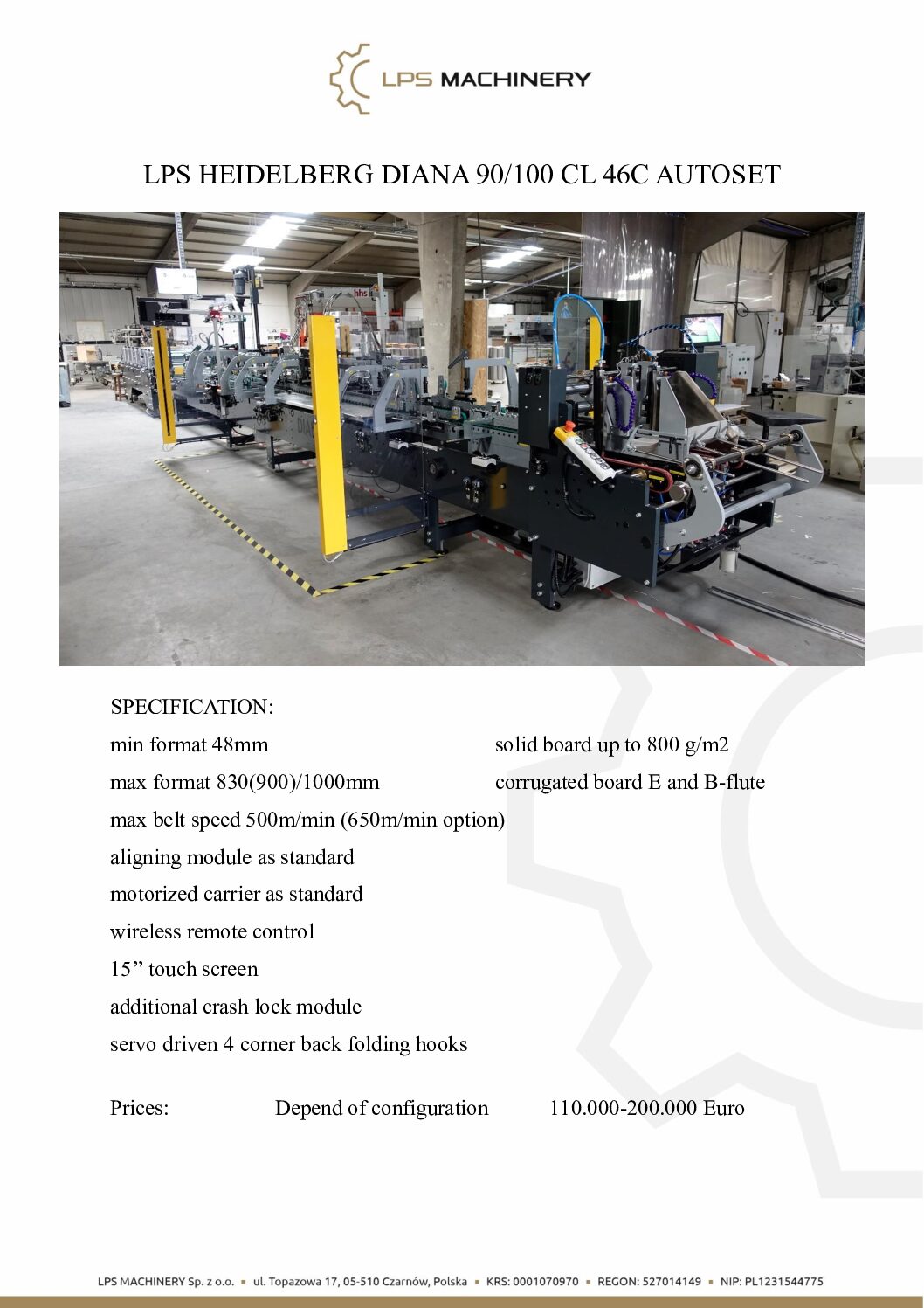

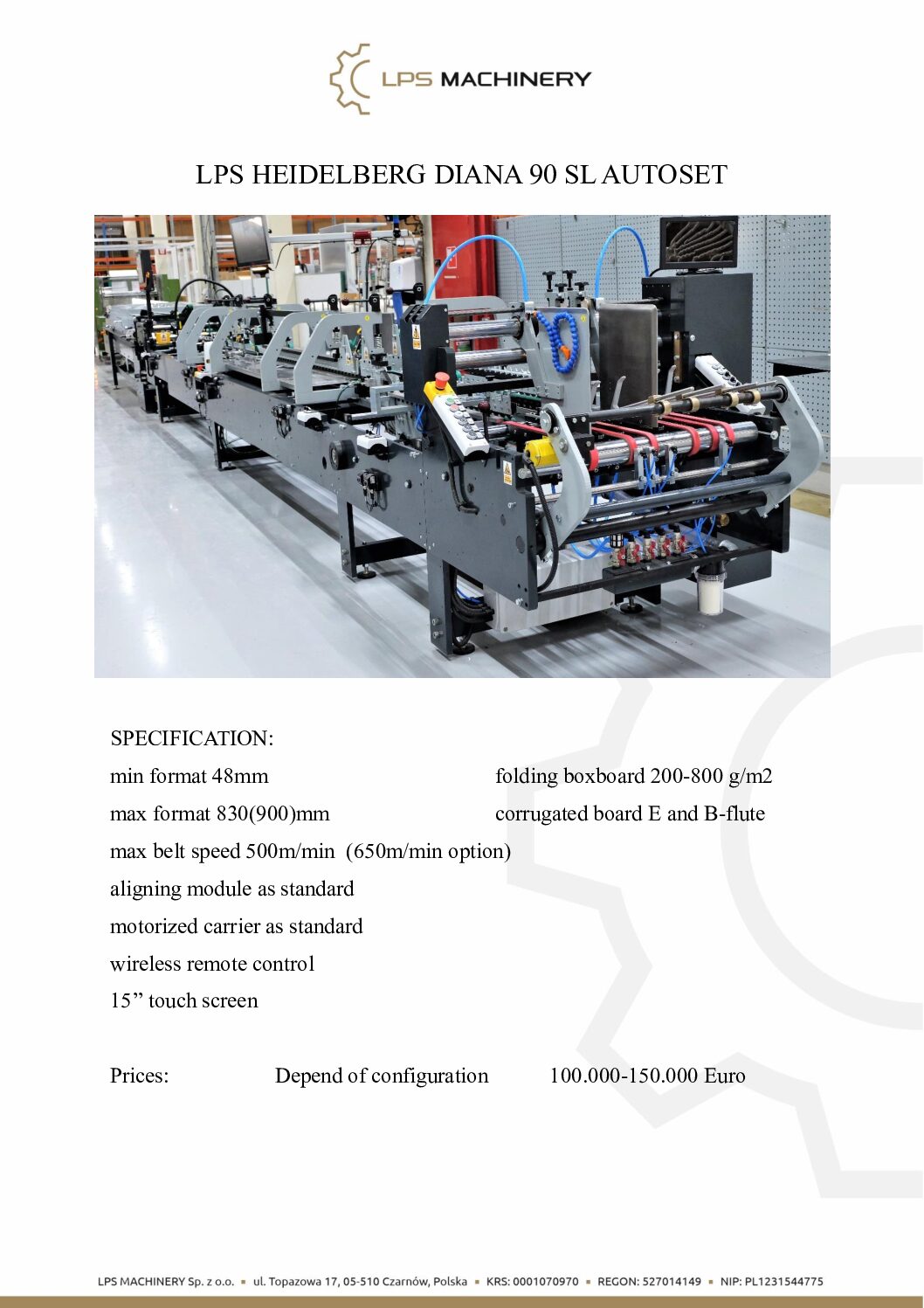

- LPS AUTOSET – automatic setting of the machine to the positions from the dimensions of the new box, or loading the position with the database of saved works, arrival of transporters with an accuracy of 0.1mm

- LPS CARRIER CONTROL – electronic position limit of all transporters preventing the collision of the transporter with the transporter or the machine fram

- LPS SAFETY SCANER SYSTEM:

- safety system based on PILZ 3D scanners on the operating side and interlocking gates on the drive side

- full integration of the system with the machine controller

- display of system information on the machine HMI screen

(Detailed information about individual modules can be found in the „Machines”->”Modules” section)

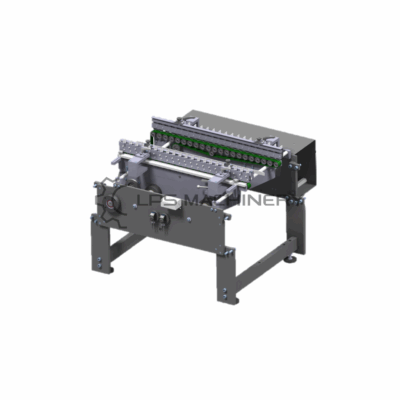

FEEDER (A)

EQUATION MODUL(A)

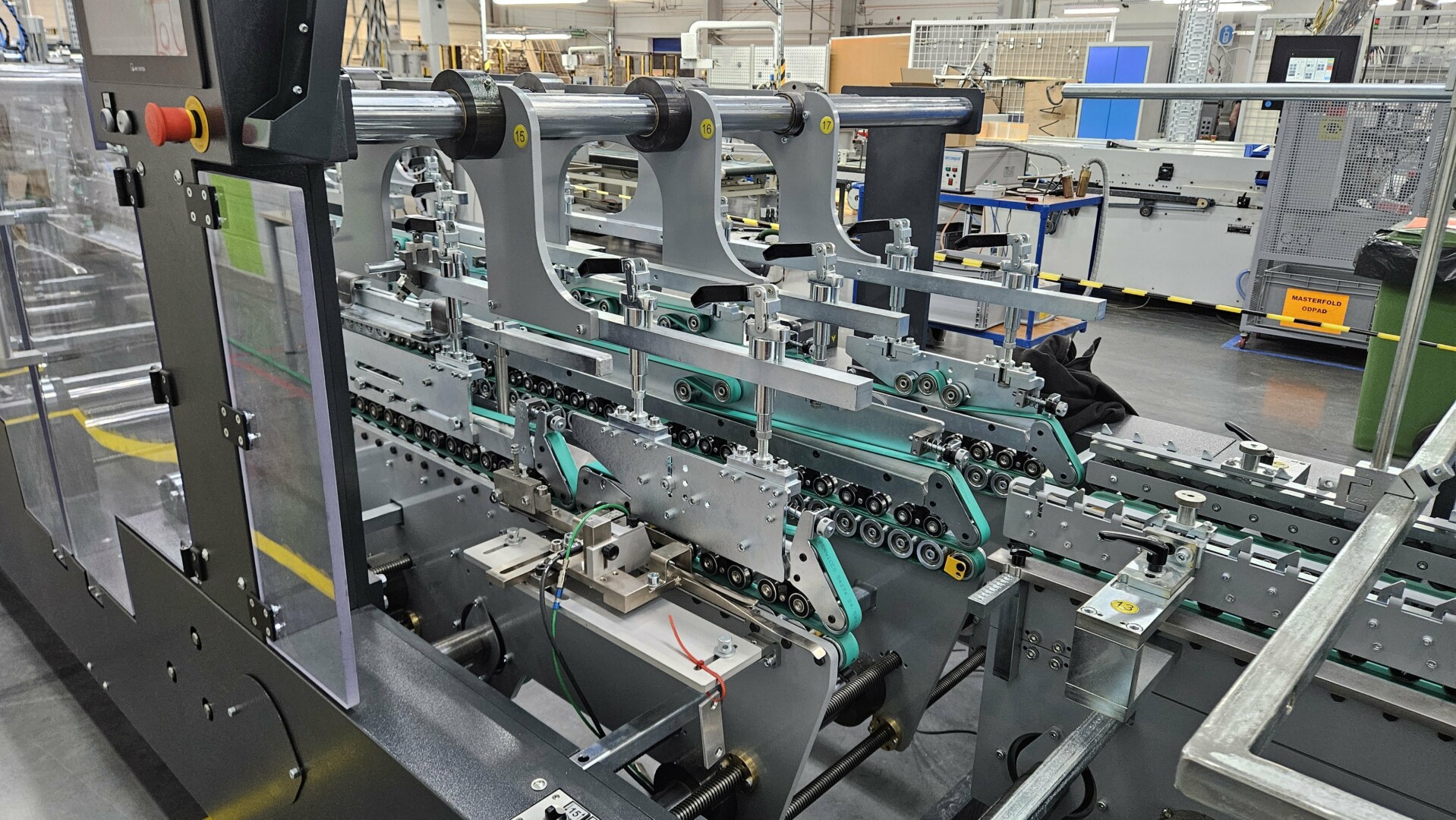

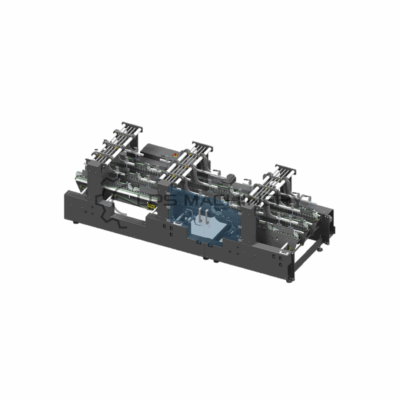

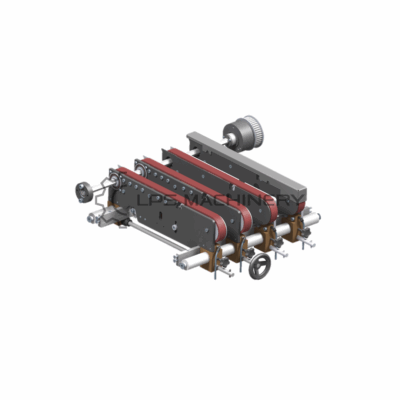

MULTIFOLDER 1(B)

MULTIFOLDER 2(C)

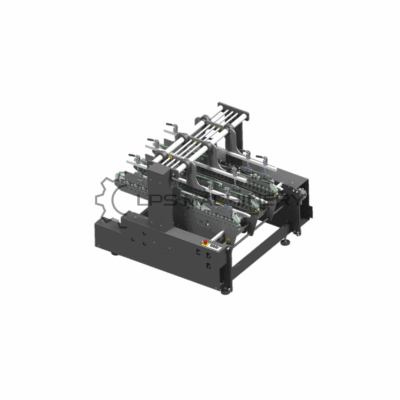

PREFEEDER MODULE(D)

REVERSING MODULE- LPS GYRO(E)

EQUATION MODUL(E)

MULTIFOLDER 3(F)

MULTIFOLDER 4(G)

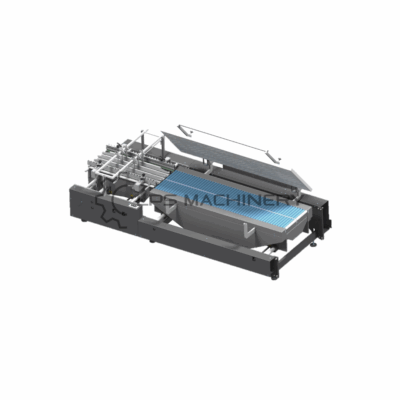

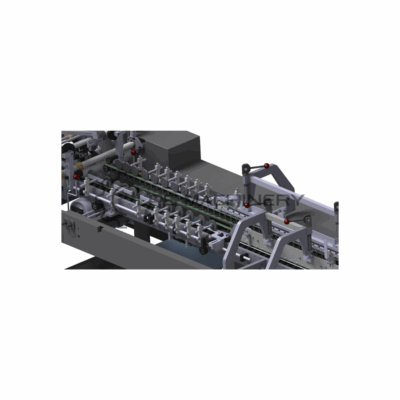

FOLDING MODULE(H)