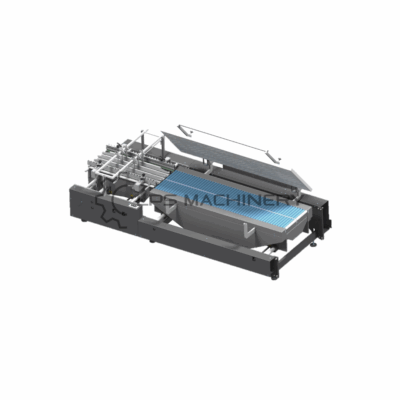

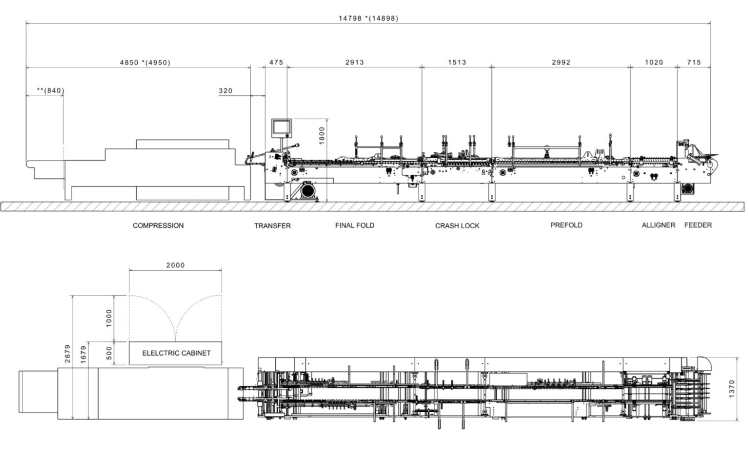

FEEDER

Specification:

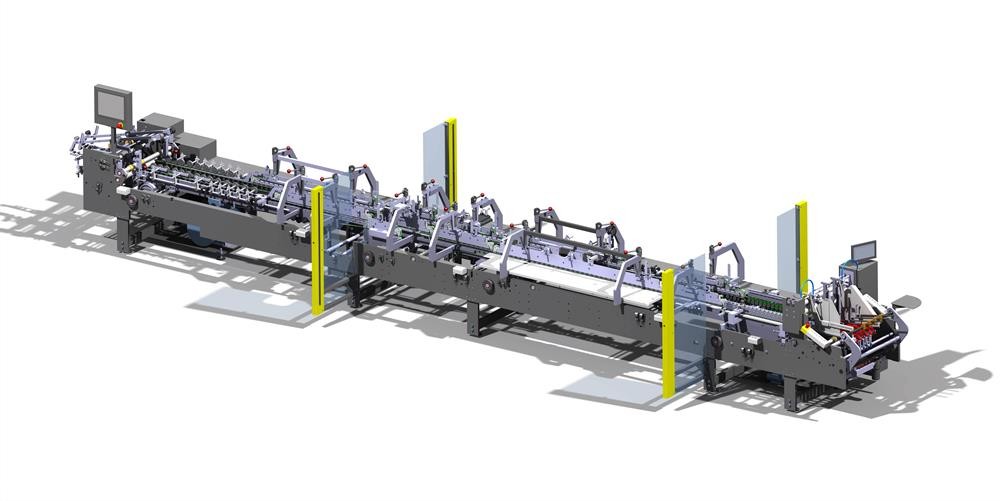

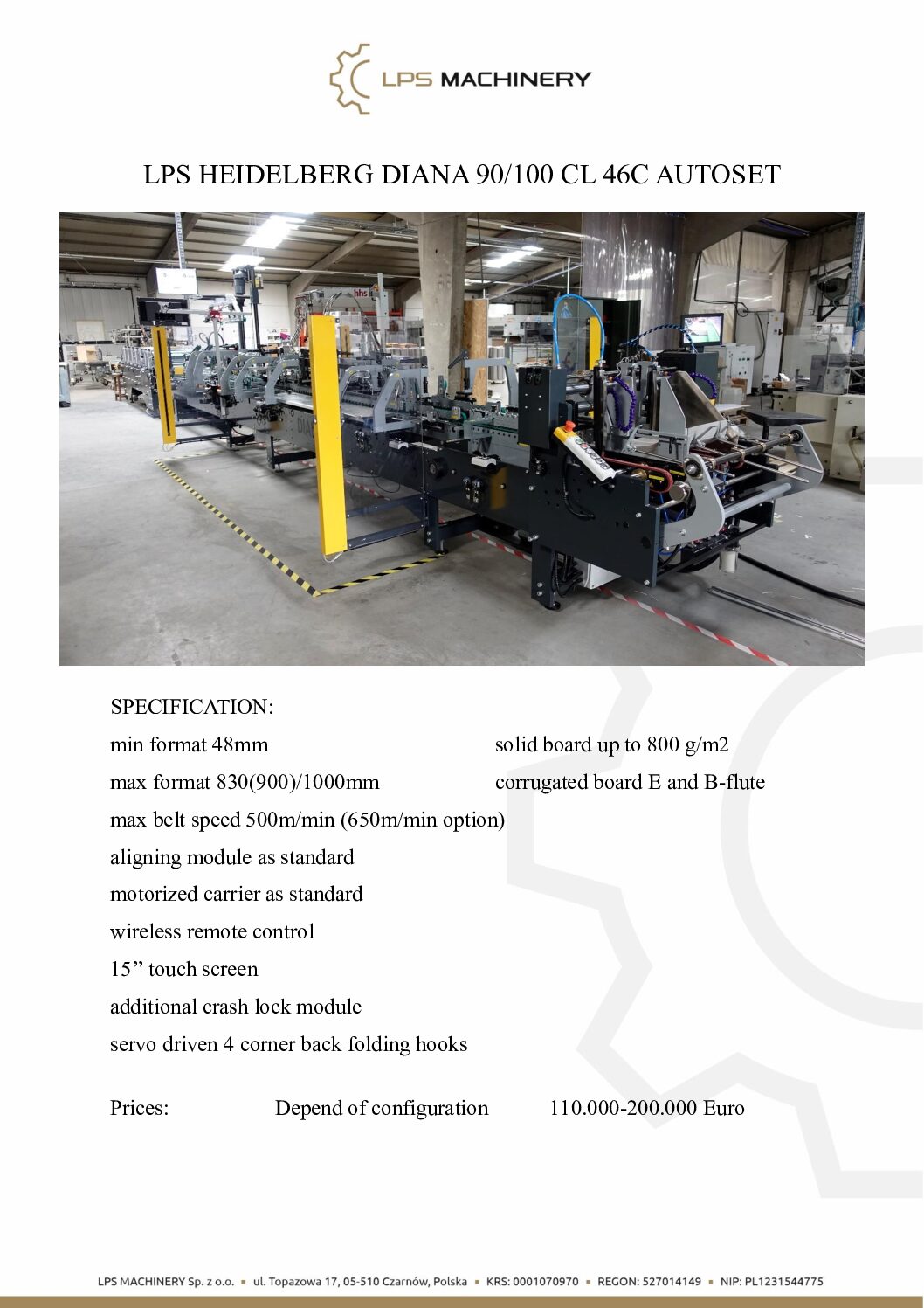

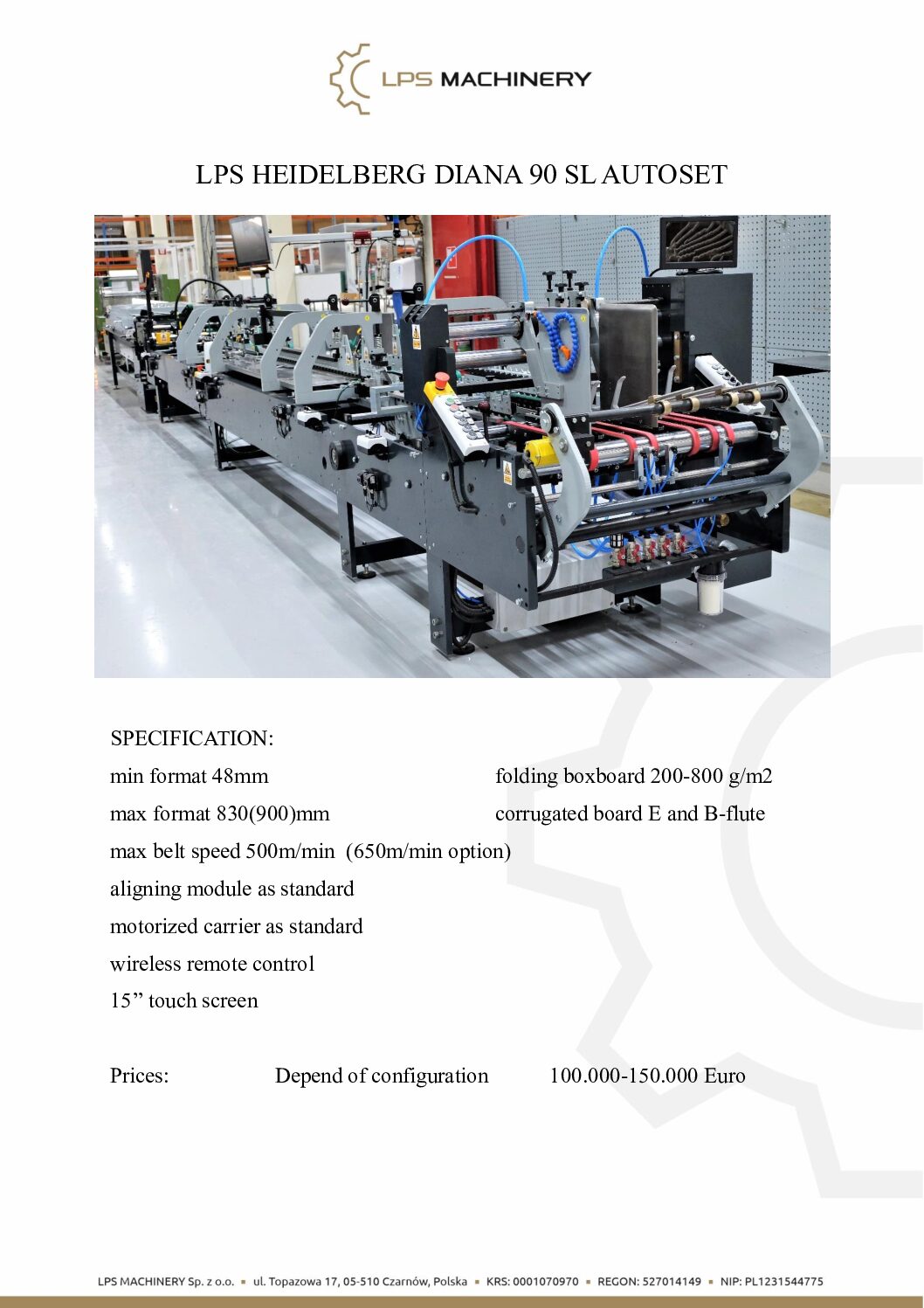

| LPS DIANA 90 | LPS DIANA 100 |

| min format 48mm | min format 48mm |

| max format 830mm | max format 1000mm |

– Feeder driven by a separate electric motor

– AUTOSET motorized gates – automatic approach to positions

– Pneumatically liftable top of the feeder

– Independent cassettes – change of position on the switched off machine

– Vacuum on 4 lanes

– Cleaning air on 4 belts

– Separating blowers

– Force-adjustable vibrator

– Monitor with camera showing the entrance to the gluing chamber

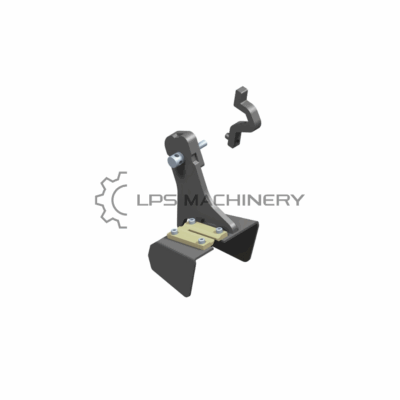

Feeder cassettes contain:

- Changing position using the rotary knob when the drive is switched off

- Safety guards for unused belts

- Cleaning brush

- Cleaning blast

- Subsys

- Vibrating Roller

- Easy belt tension replacement and adjustment

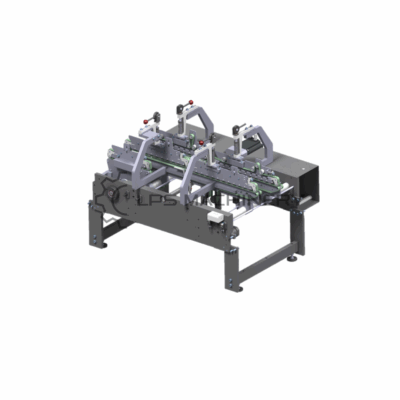

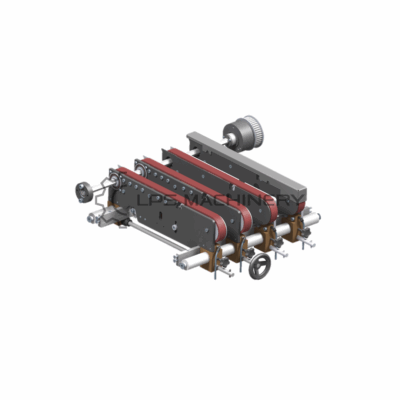

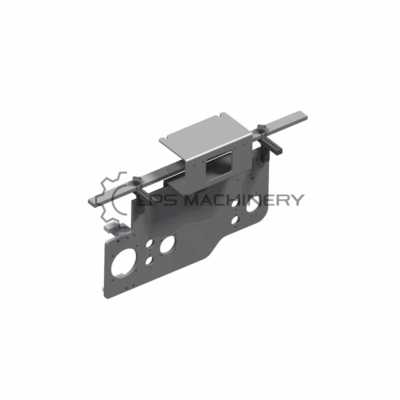

UPPER CARRIERS

LPS Diana is equipped with modern upper transporters.

- The innovative LPS CLAMPING SYSTEM allows the tooling to be installed anywhere on the conveyor

- Adjustment of the input roller with a knob.

- Easy and effective belt tensioning

- Easy adjustment of the conveyor position

- Easy adjustment of the roller pressure

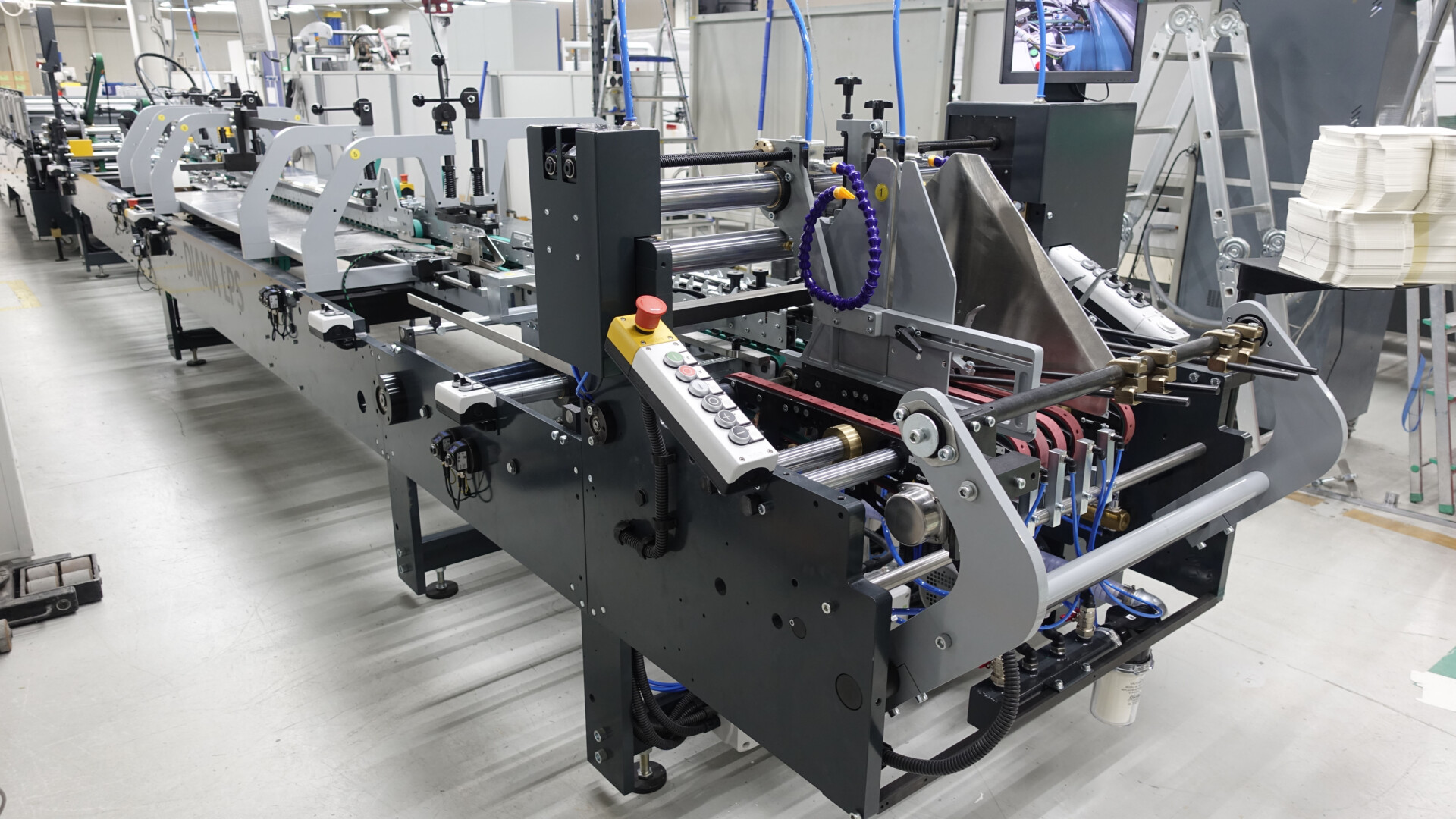

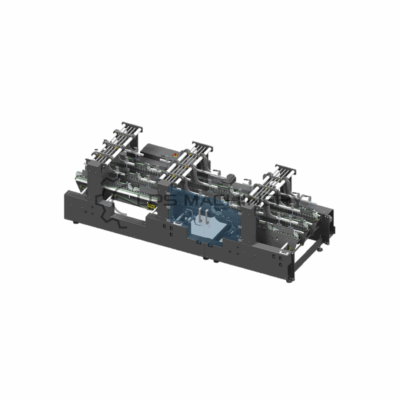

DRIVES AND ELECTRONICS

LPS DIANA is powered by modern energy-saving motors in IE3 class controlled by ABB inverters and SIEMENS PLC

- An additional glue wheel drive motor allows you to use the LPS GP AUTO function – the machine is stationary, the glue wheel is moving, the glue remains fresh during a break

- Feeder drive motor – the gap between cartons set on the HMI screen in mm

- Transfer section drive motor – section speed set in % on the MHI screen

- Belt drive for quiet and maintenance-free operation

- The plastic coupling eliminates the transmission of vibrations from the drive wheel to the drive shaft of the transport belts.

- Powerful bearings ensure maintenance-free and long-lasting operation

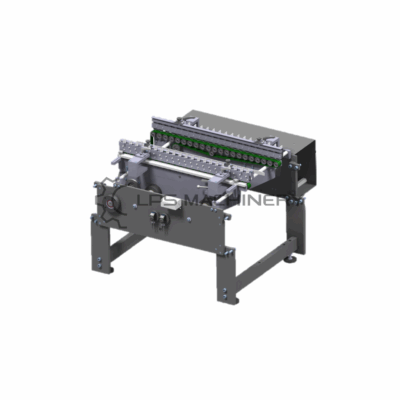

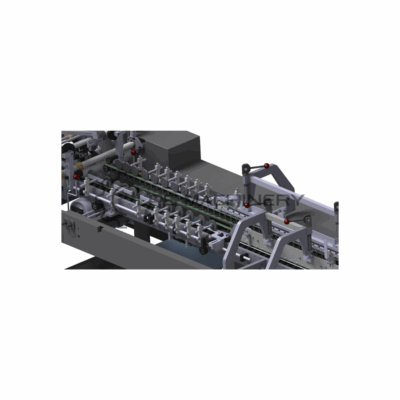

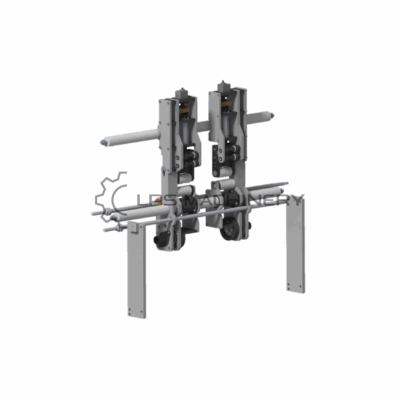

ALIGNER

LPS DIANA is equipped with a modern alignment module. AUTOSET motorized transporters provide automatic approach to the position.

All changes to the equation module setting do not require any tools.

- Very easy lifting and lowering of the pressure rollers

- Simple pressure adjustment at the front and rear of the carrier

- DATUM can be set in 8 positions on the left and right.

- Quick repositioning of the rollers on the belt

- Quick change of cutting level

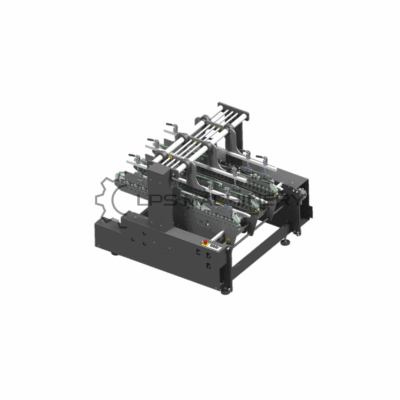

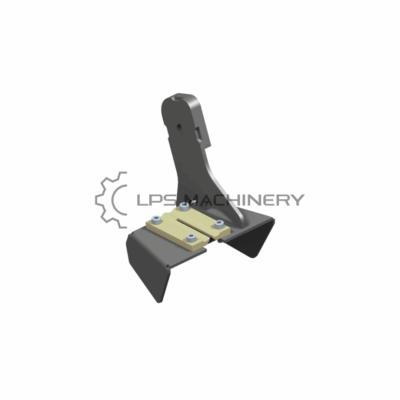

FINAL FOLDING MODULE

Module length 290cm for final folding. AUTOSET motorized transporters provide automatic approach to the position. Large touch screen to control the machine and the database of saved works.

- Smooth speed change of the upper folding belts

- Bobst style folding rollers

- The unique Jagenber-style design allows you to move the right transporter to the right lower belt and fold a cardboard box with a total width of at least 48mm without any additional equipment.