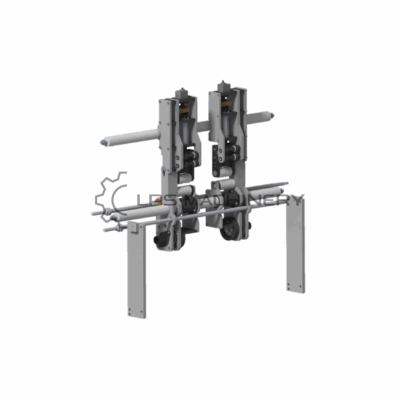

MONITORING PRINCIPLE

1. OPERATOR SIDE

– PILZ monitoring scanners (OPTION: SICK, KEYENCE)

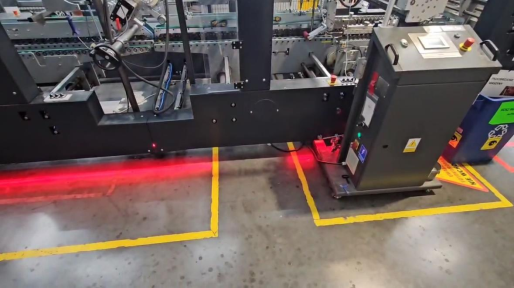

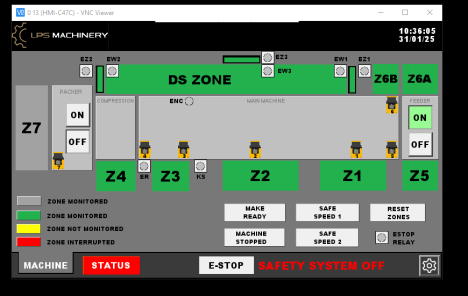

OPTION: ZONES SELECTOR:

– secured area is divided into zones, allowing one of the zones to be muted to use special tooling like plasma gun, hot melt or label machine installed in secured area

– NOT SECURED ZONE IS LIGHTED WITH RED LINEAR LED LIGHT

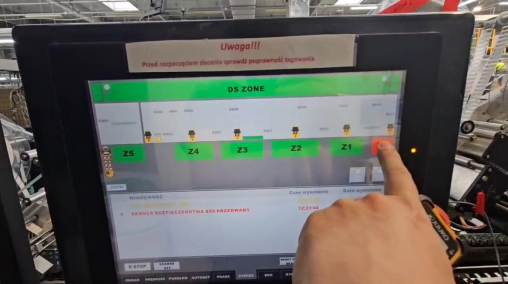

OPTION: HMI, TOUCH SCREEN

– HMI touch screen helps operator to find the disturb area, every scaners and interlock doors are shown with status green or red

– BENEFIT – SETTINGS AND ERRORS LOGS LIST with recorded time of occurrence for event diagnosis

OPTION: PULL CORD (SAFETY ROPE):

– additional safety guaranteed thanks to the safety rope installed along the entire length of the machine

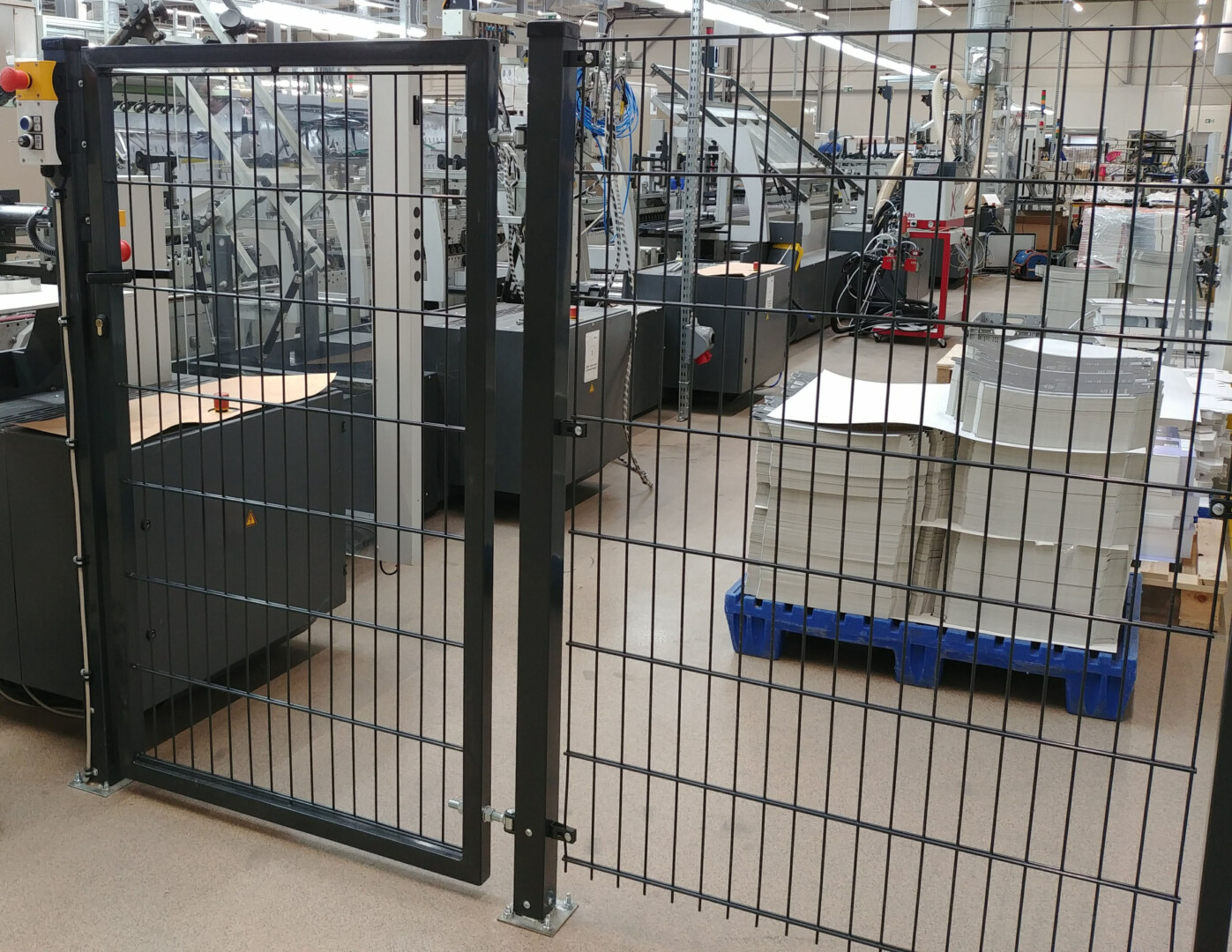

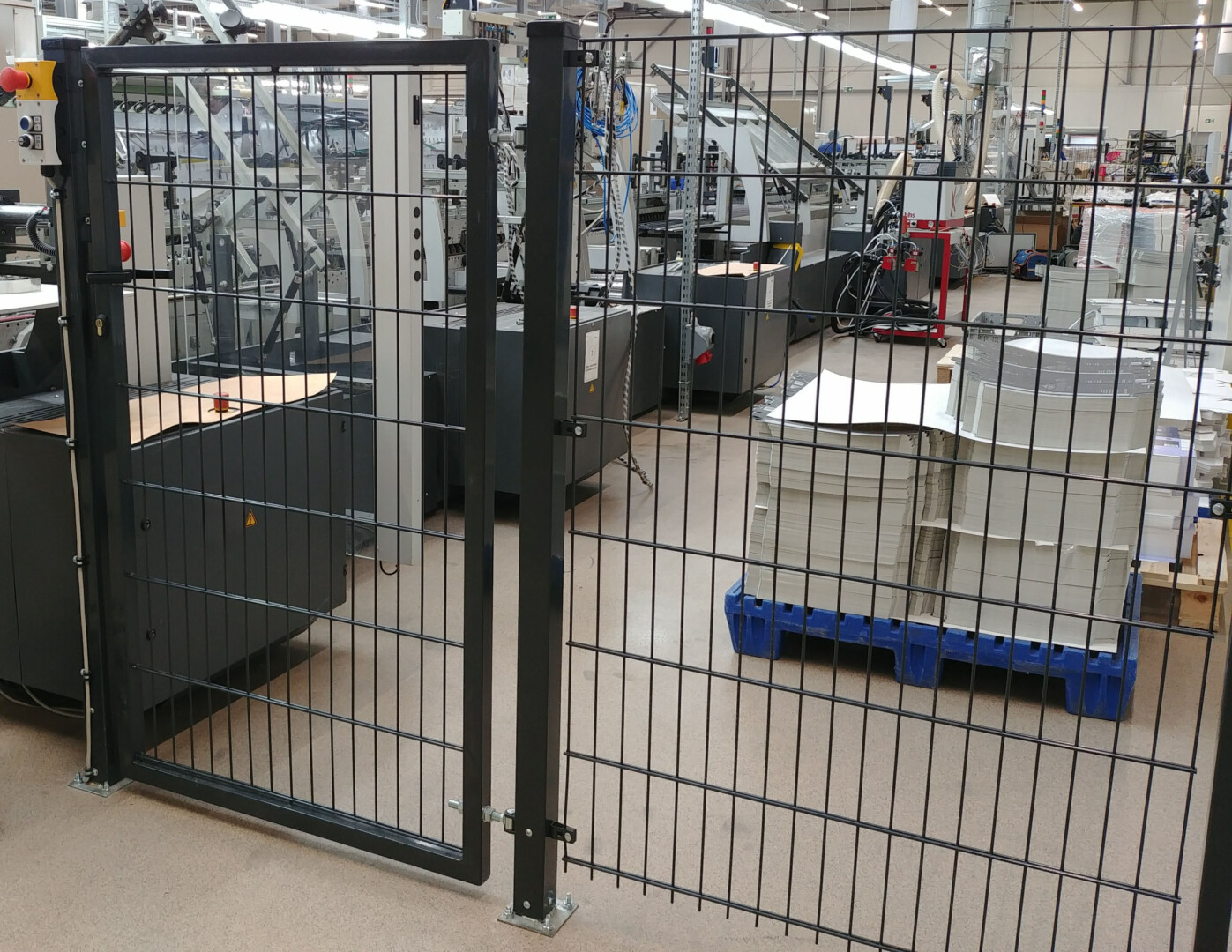

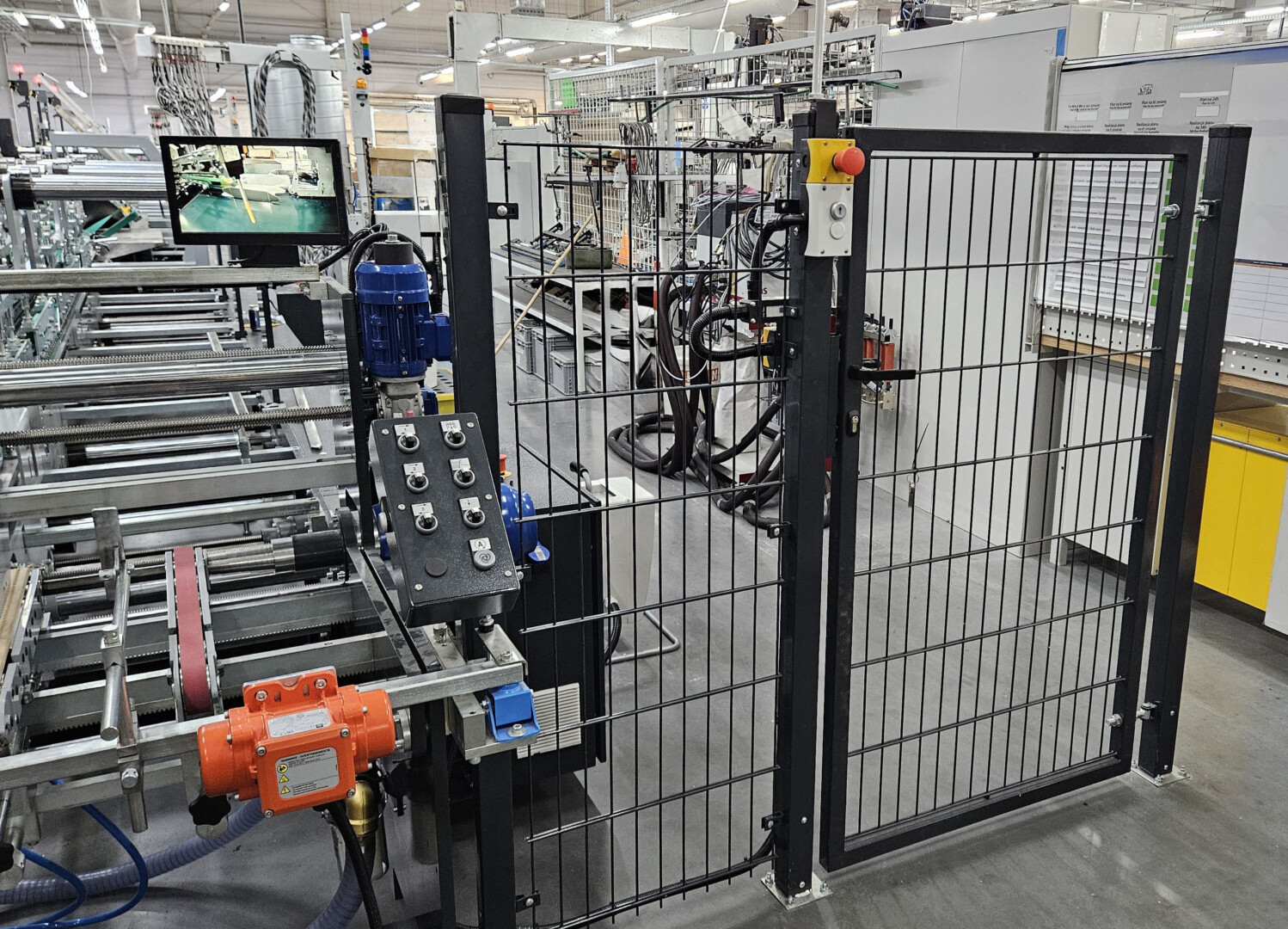

OPTION: DRIVE SIDE FENCE WITH INTERLOCK GATES:

– drive side of the machine is secured with interlock gates and fence

– standard is one gate at the feeder and one gate at the compression

– during machine operation gates are closed mechanically with PILZ interlock

– door opening mechanism from the inside in case of snapping by third parties